World Leader In IR-electrochromic Materials and the Related Variable Emittance Materials

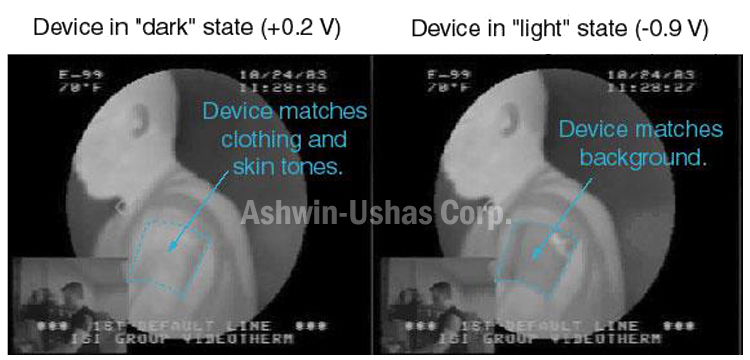

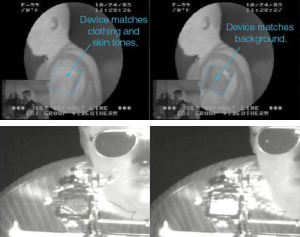

Camouflage via chameleon-like matching with the background, not in the Visible spectral region that the human eye sees in, but rather in the mid- and long-wave infrared region (MWIR, LWIR, 3 to 12 microns). Yields an overwhelming advantage in night operations. A complete camouflage countermeasure against IR cameras operating in these spectral regions. (These IR cameras are not night-vision cameras, which operate in the near-IR to about 2 microns and need some ambient light to work- they don’t work on moonless nights.)

Camouflage via chameleon-like matching with the background, not in the Visible spectral region that the human eye sees in, but rather in the mid- and long-wave infrared region (MWIR, LWIR, 3 to 12 microns). Yields an overwhelming advantage in night operations. A complete camouflage countermeasure against IR cameras operating in these spectral regions. (These IR cameras are not night-vision cameras, which operate in the near-IR to about 2 microns and need some ambient light to work- they don’t work on moonless nights.)

IR Electrochromic Materials

- IR-electrochromic materials change “color” in the IR, dynamically. This “color” is variable and can be adaptive, i.e. matching the background, much like a chameleon, except in the IR.

- These materials can thus provide camouflage countermeasures, in threat situations, against IR cameras operating in the 3 to 12 μm regions. These cameras are not night-vision devices, which operate in the near-IR (0.9 to 1.5 μm) region and are in reality image-intensifiers which need some, minimal light to operate (they do not work on, e.g., moonless nights). Such adaptive, IR camouflage can give tremendous advantage in night operations.

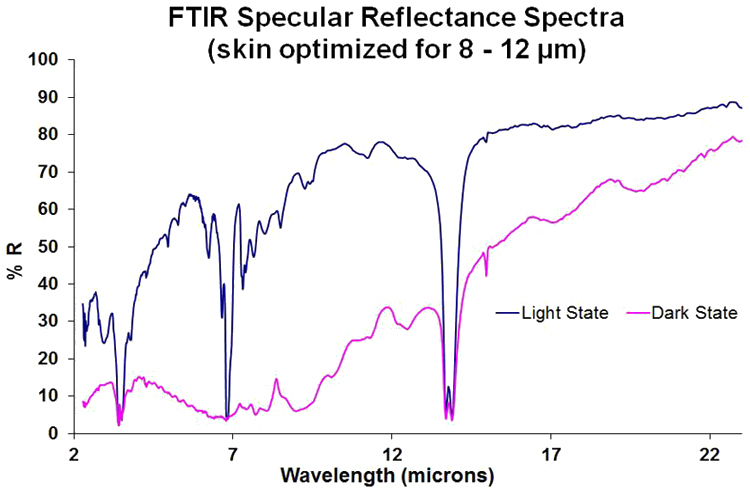

- Performance can be judged by several parameters, e.g. %-Reflectance (%R) contrast in the IR, apparent temperature variation and emittance (integrated emissivity).

Ashwin’s Technology

- Ashwin’s patented dynamic (switchable) IR-electrochromics technology is based on Conducting Polymer (CP) IR-electrochromics, a unique skin design, and a “smart” Controller for efficient, adaptive camouflage.

- They have low power (+/- 3 VDC, < 50 μW/cm²), extremely low cost.

- The electrochromic skins are thin (< 0.5 mm), flexible, very lightweight (0.12 g/cm² or 1.2 kg/m²), extremely durable, cuttable with scissors to any shape/size/area, affixable to any surface.

- Typical performance:

- 76% (extreme light, low-emissivity state) to 4% (extreme dark, high-emissivity state) at 10 μm (LWIR), as measured by FTIR Specular Reflectance.

- 55% (extreme light state) to 13% (extreme dark state) at 5.5 μm (MWIR), as measured by FTIR Specular Reflectance.

- Values “dialable” to any intermediate values between above light/dark extremes.

- Skins can be optimized for the MWIR, LWIR or both.

- Switching Time, for full switching between extreme light and extreme dark states is < 2 s.

- Matching to all kinds of backgrounds, from cold sky, water and foliage to soil, desert sand and man-made structures like buildings, vehicles and soldier uniforms.

- Demonstrated to have excellent durability against expected environmental conditions, including sand blasts, wind, heavy rain and extreme temperatures (-40 to +80°C).

- Superior in performance as well as cost to competing technologies such as Peltier plates, other electrochromic systems, thermochromic systems.

Learn more…

- IR-ELECTROCHROMIC SKINS PRIMER

- DESCRIPTION OF ASHWIN IR-ELECTROCHROMIC SKINS

- PERFORMANCE

- COMPARISON OF PERFORMANCE AND COST WITH COMPETING TECHNOLOGIES

- DATA: CONSTRUCTION, APPEARANCE

- DATA: TYPICAL PERFORMANCE DATA

- RELEVANT LITERATURE REFERENCES

- AVAILABILITY AND FURTHER INFORMATION

INFRARED (IR)-ELECTROCHROMICS PRIMER

- IR-electrochromic materials change “color” in the IR. This “color” is variable and can be adaptive, i.e. matching the background, much like a chameleon, except in the IR.

- These materials can thus provide camouflage countermeasures, in threat situations, against IR cameras operating in the 3 to 5 μm (mid-wave IR, MWIR) and 8 to 12 μm (long-wave, LWIR) regions. These cameras are not night-vision devices, which operate in the near-IR (0.9 to 1.5 μm) region and are in reality image-intensifiers which need some, minimal light to operate (they do not work on, e.g., moonless nights).

- Such adaptive, IR camouflage can give tremendous advantage in night operations.

- Performance can be judged by several parameters, e.g.:

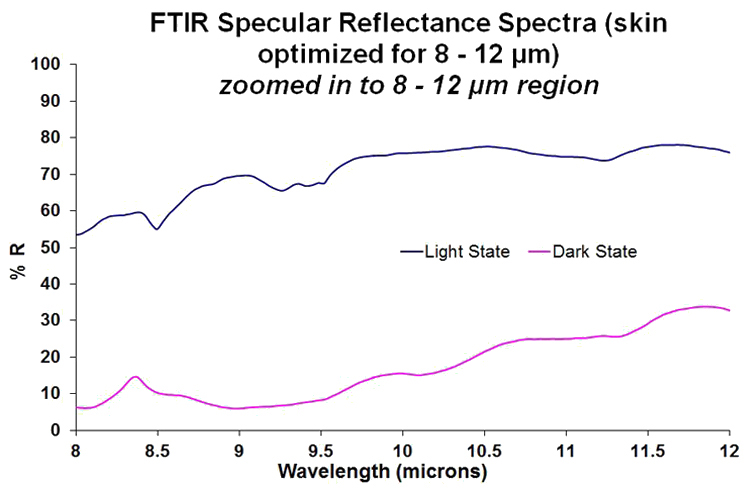

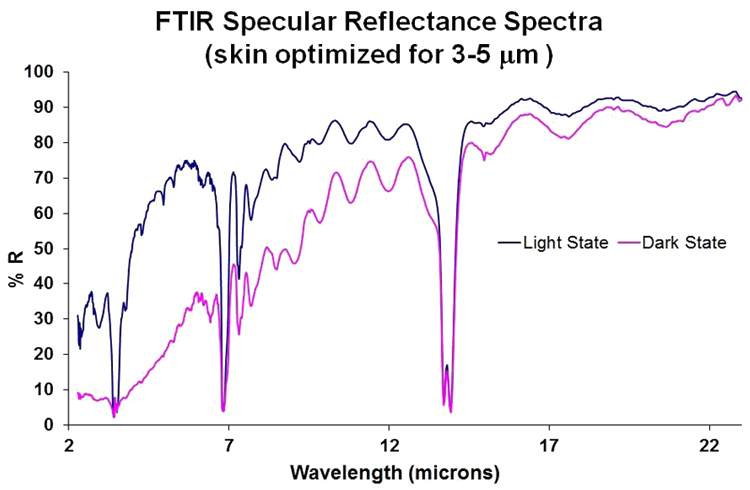

- IR Reflectance spectra in the two spectral regions of interest (3 to 5 μm (mid-wave IR, MWIR) and 8 to 12 μm (long-wave, LWIR)). Typically, Specular (rather than Diffuse) spectra give the most information. The larger the contrast between light and dark states, the better the performance.

- Apparent temperature, as measured by an IR camera. For best camouflage, the temperature of the IR-electrochromic skin should be as close as possible to that of the background that one is trying to match.

- Emittance (integrated emissivity). See description of Ashwin-Ushas Variable Emittance Skins.

DESCRIPTION OF ASHWIN IR-ELECTROCHROMIC SKINS

- Patented technology based on:

- Conducting Polymer (CP) as the active IR-electrochromic, yielding the variable IR signature.

- Unique design, allowing direct exposure of active IR-electrochromic to external environment and single-microporous-membrane construction.

- Thin (< 0.5 mm), flexible, very lightweight (0.12 g/cm² or 1.2 kg/m²), extremely durable skins, cut with scissors to suit any shape/size and area.

- Can be affixed to any surface.

- Operate with small, applied DC voltage (less than +/- 3 VDC).

- “Smart” Controller for efficient, adaptive camouflage.

- Extremely low cost.

PERFORMANCE

- Typical IR contrast:

- 76% (extreme light, low-emissivity state) to 4% (extreme dark, high-emissivity state) at 10 μm (LWIR), as measured by FTIR Specular Reflectance.

- 55% (extreme light state) to 13% (extreme dark state) at 5.5 μm (MWIR), as measured by FTIR Specular Reflectance.

- Corresponding emittance variations are ca. 0.15 to 0.80.

- Values “dialable” to any intermediate values between above light/dark extremes.

- Skins can be optimized for LWIR, MWIR, or both. Quasi-independent control of IR and Visible signatures.

- Switching Time, for full switching between extreme light and extreme dark states is < 2 s.

- Matching to all kinds of backgrounds, from cold sky, water and foliage to soil, desert sand and man-made structures like buildings, vehicles and soldier uniforms.

- Cyclability: Tested to 10,000 light/dark cycles without significant degradation.

- Demonstrated to have excellent durability against expected environmental conditions, including sand blasts, wind, heavy rain and extreme temperatures (-40 to +80°C).

- Power requirements: +/- 3 VDC, < 50 μW/cm².

- Indefinite shelf life in packaging and at storage temperatures between -20 and +50°C.

COMPARISON OF PERFORMANCE AND COST WITH COMPETING TECHNOLOGIES

- Essentially no competing technology with even comparable performance. Examples of extant, competing technologies:

- Arrays of Peltier plates which are actively, rapidly heated/cooled. These are primarily for countermeasures against night-vision, i.e. near-IR, have very high power requirements and, of course, do not work in the MWIR or LWIR. They are also very expensive and bulky.

- Other electrochromic systems, e.g. those based on poly (2,7 carbazole) derivatives. These have extremely poor IR performance, no match for our systems.

- Thermochromic systems, e.g. those based on, and choleric liquid crystals, or active heating of a metallized plastic surface. These again have extremely poor IR performance, no match for our systems.

- Other variable emittance technologies developed for use in space are not suitable for adaptive, terrestrial IR-camouflage. (See description under Ashwin-Ushas Variable Emittance Skins).

- 1⁄5 to 1⁄10 the cost of other technologies described above (which in any case do not work well in the MWIR and LWIR).

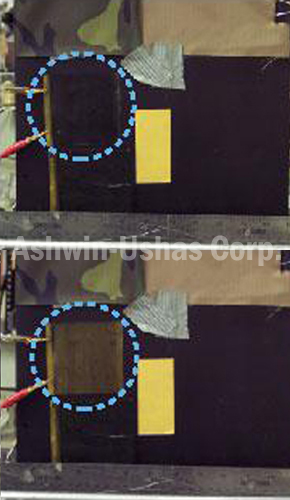

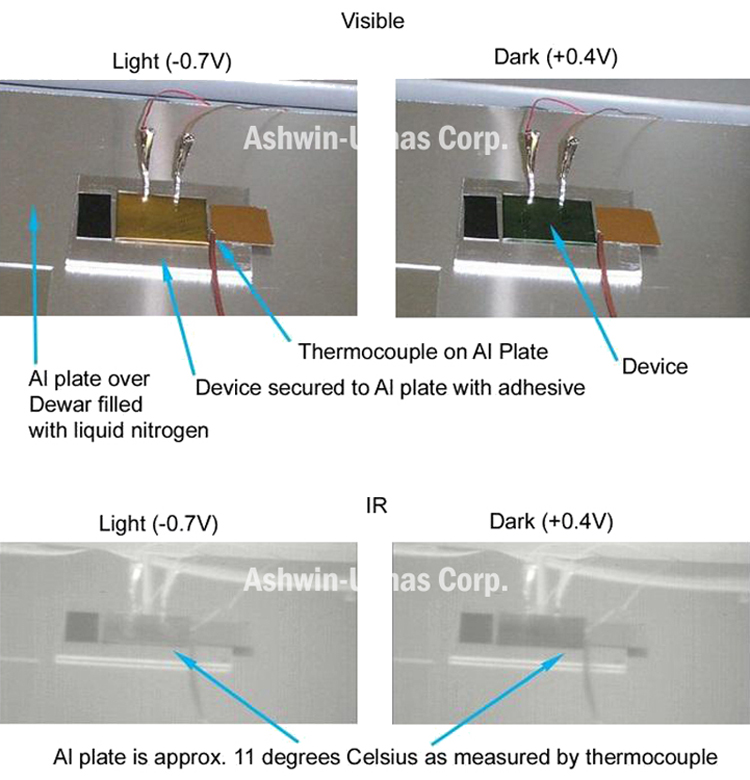

DATA: CONSTRUCTION, APPEARANCE

Click images to enlarge.

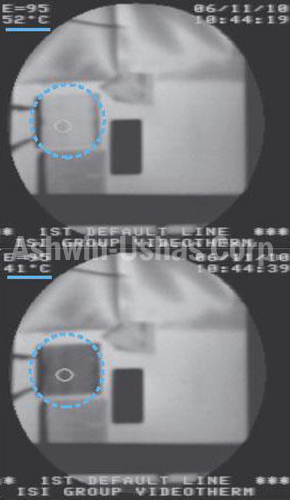

LWIR (8 – 12 μm) images with IR-electrochromic skin mounted on Cu plate heated to 66°C:

The tailorable variation of the apparent temperature (i.e. IR signature), as shown, allows matching with different backgrounds.

MWIR (3 – 5 μm) images with IR-electrochromic skin mounted on Al plate cooled from behind to 11°C:

Bottom row: Left and Right, respectively, light (non-emissive) and dark (emissive) state of skin.

Top row: Same, Visible-region photo.

DATA: TYPICAL PERFORMANCE DATA

Click tables and graphs to enlarge.

LWIR (8 – 12 μm) data

MWIR (3 – 5 μm) data

RELEVANT LITERATURE REFERENCES

Our Technology

- Journal of Applied Polymer Science, 2014, 131(19), 40850 (October 2014); DOI: 10.1002/app.40850

- National Aeronautics and Space Administration, NASA Publications (downloadable pdf)

Competing Technology

- Adaptiv, Active Camouflage Technology

- Multicolored Electrochromic Cells Based On Poly(2,7-Carbazole) Derivatives For Adaptive Camouflage

- Thermal/optical Camouflage with Controlled Heat Emission

- Thermal and Visual Camouflage System

- Passive Control of Emissivity, Color and Camouflage

AVAILABILITY AND FURTHER INFORMATION

For inquiries, please Contact Us.